Custom Plastic Manufacturing Processes

We manufacture components made from a wide range of plastics – from polypropylene, PP copolymer, homopolymer and compounds, through nylons, glass filled nylons and PVC polyvinyl chloride to Evoprene®, Santoprene® and other TPEs, TPR, TPU and TPV (see below for full list of polymers we work with).

We can provide compounds that are flame retardant, chemical resistant, military grade, WRAS / Water Safe / Water Council / British Gas / UL approved, and that comply with Food Quality Standards, Medicine & Healthcare regulations and British Standards. We also have a Class 7 Clean Room for inspection and finishing.

Scope of Horiaki In Plastic Products

Rapid prototyping options

Low to high volume production

Plastic to plastic bonding

Bonding to rubber/metal/fabric

Threaded / other holes

Assembly and finishing

Products

Bushes

Plastic bushes, also known as plastic bushings or plastic bearings, are mechanical elements made of plastic materials. They are used in plastic products for several purposes:

Friction Reduction

Noise Dampening

Component Separation

Load-Bearing Support

Wear Resistance

Corrosion Resistance

Cable connectors

Cable connectors in the context of plastic products are components or devices used to establish electrical or electronic connections between cables or wires. These connectors are made from plastic materials and serve several important functions within electrical or electronic systems. Here are some key aspects of cable connectors with respect to plastic products:

RJ45 Connectors

USB Connectors

Audio and Video Connectors

Power Connectors

Circular Connectors

Coaxial Connectors

Feet

Plastic feet serve various functions and are designed to provide stability, protection, and other benefits to the product and its environment. Here are some common aspects of feet with respect to plastic products:

Stability

Surface Protection

Noise Reduction

Anti-Skid

Adjustability

Ferrules

Ferrules refer to small, typically cylindrical, and often tapered sleeves or caps made of plastic material. These components serve various functions within different applications and industries. Here are some common aspects of ferrules with respect to plastic products:

Cable Management

Crimping and Termination

Protection and Insulation

Hollow Ferrule

Fuse covers

Fuse covers refer to protective enclosures or caps made of plastic that are designed to cover and secure electrical fuses. These covers serve several important functions in electrical systems and equipment. Here are some common aspects of fuse covers with respect to plastic products:

Protection

Safety

Durability

Easy Installation

Gaskets

plastic gaskets are versatile components that play a crucial role in ensuring the integrity, functionality, and safety of various plastic products and systems by creating effective seals and barriers. They are found in a wide array of applications across industries such as automotive, aerospace, manufacturing, and more.

Sealing

Protection

Vibration and Noise Dampening

Heat Resistance

Compression and Load Distribution

Grommets

Plastic grommets, in particular, offer benefits such as lightweight design, corrosion resistance, and ease of installation. They are commonly used in various industries for their versatility and ability to enhance the durability and functionality of products.

Reinforcement

Sealing

Noise Reduction

Aesthetic and Decorative

Pipe connectors

Plastic pipe connectors are essential components in the construction, repair, and maintenance of pipe systems. They provide secure and reliable connections while offering flexibility and adaptability for different plumbing and fluid transport needs.

Connection Types

Threaded and Threadless

Quick and Tool-Free Installation

Chemical Resistance

Temperature and Pressure Ratings

Sealing

Size and Compatibility

Plugs

plugs are versatile components that play a crucial role in maintaining the functionality, safety, and cleanliness of various plastic products, equipment, and systems by providing effective closure and protection.

Closure

Leak Prevention

Ventilation Control

Versatility

Sleeves

Plastic sleeves are versatile components that play a crucial role in protecting, organizing, and enhancing the functionality of various plastic products, systems, and packaging. Their design and application can vary widely depending on the specific use case and industry.

Heat Shrinkable

Cable Management

Corrosion Resistance

Sealing and Tamper-Evidence

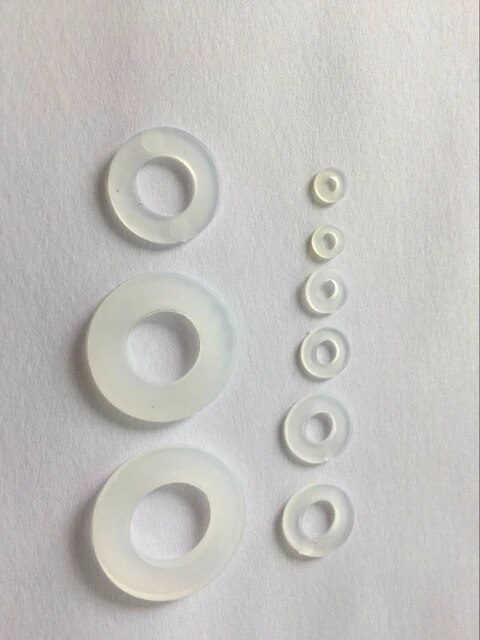

Washers

Washers refer to flat, disc-shaped components made of plastic material that are used in various applications to distribute loads, reduce friction, and create a sealing or spacing effect. Plastic washers serve several important functions in different industries and products. Here are some common aspects of washers with respect to plastic products:

Friction Reduction

Sealing

Insulation

Spacer and Shim