Materials

What is Rubber Moulding?

Characteristics and inspection of elastomers

Hardness

One of the most often named properties regarding Polymer materials is hardness. Even so the values can be quite misleading. Hardness is the resistance of a body against penetration of an even harder body – of a standard shape defined pressure. There are two procedures for hardness tests regarding test samples and finished parts made out of elastomer material:

1. Shore A/D according to ISO 48 / DIN 53 505 / ASTM D 2240 Measurement for test samples

2. Durometer IRHD (International Rubber Hardness Degree) according to ISO 48 / DIN 53 519-1 and -2 / ASTM 1414 and 1415

Measurement of test samples and finished parts

The hardness scale has a range of 0 (softest) to 100 (hardest). The measured values depend on the elastic qualities of the elastomers, especially on the tensile strength. The test should be carried out at temperatures of 23 ±2 °C – not earlier than 16 hours after the last vulcanisation process (manufacturing stage). If other temperatures are being used this should be mentioned in the test report. Tests should only be carried out with samples which have not been previously stressed mechanically.

Silicone

Silicone rubber is an elastomer (rubber-like material) composed of silicone — itself a polymer — containing silicon together with carbon, hydrogen, and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations. Silicone rubbers are often one- or two-part polymers, and may contain fillers to improve properties or reduce cost. Silicone rubber is generally non-reactive, stable, and resistant to extreme environments and temperatures from -67 °F to 572 °F (-55 °C to 300 °C) while still maintaining its useful properties. Due to these properties and its ease of manufacturing and shaping, silicone rubber can be found in a wide variety of products, including: voltage line insulators, automotive applications; cooking, baking, and food storage products; apparel such as undergarments, sportswear, and footwear; electronics; medical devices and implants; and in home repair and hardware with products such as silicone sealants.

Common Name: Silicone

ASTM D-2000 Classification: FC, FE, GE

Chemical Definition: Polysiloxane

Temperature Range

Low Temperature Usage: -60° to -150° F | -50°C to -100°C

High Temperature Usage: Up to 480° F | Up to 250°C

Industrial Classifications

Liquid Silicone Rubbers (LSR)

Also called heat curable liquid materials. Processed on specially designed injection molding and extrusion equipment.

High Temperature Vulcanizing (HTV)

Also called heat curable silicone, these materials usually are in a semi-solid gum form while in the uncured state. Rubber-type processing is required to produce finished items.

Room Temperature Vulcanizing (RTV)

usually comes in the form of a flowable liquid. Commonly used for sealants, mold making, encapsulation and potting. RTV materials are generally not used as conventional rubbers.

About Liquid Silicone Rubber (LSR)

Liquid silicone rubber (LSR) and silicone rubber are extraordinary manufactured materials. By combining the appropriate additives, in the correct amounts, silicone is transformed into a highly specific material.

It can insulate. Or it can be conductive.

Silicone can withstand freezing temperatures. And it can stand up to high heat.

It can be translucent. It can also be almost any color – even glow-in-the-dark green.

Silicone resists fungus. At the same time, it is non-toxic.

From the cleanroom to the operating room, from the dashboard to the circuit board, silicone rubber exhibits such a wide range of properties, it is used in many applications where organic rubber cannot perform.

Silicone Compounds

Silicone rubber material can be compounded in different ways to meet any number of applications. Silicone fillers can also improve the tensile strength to be in the area of 1500 PSA and tear resistance up to 200lbs. Flame retardant additives can be added to increase fire resistant properties. Carbon black additive will also increase the silicone’s electrical conductivity. Silicone is a very clean rubber with low odor and taste. In addition to temperature resistance, other advantages of silicone rubber include insulation from electricity, compression set resistance, and the ability to repel water. Because of these advantages, silicone rubber is a versatile material for many industries Custom silicone rubber parts can be used in the production of:

Extruded rubber products

Rubber gaskets

Rubber seals and tubing

Molded rubber products

Fkm

FKM (by ASTM D1418 standard) (equivalent to FPM by ISO/DIN 1629 standard) is the designation for about 80% of fluoroelastomers as defined in ASTM D1418. All FKMs contain vinylidene fluoride as a monomer. Fluoroelastomers are more expensive than neoprene or nitrile rubber elastomers. They provide additional heat and chemical resistance. FKMs can be divided into different classes on the basis of either their chemical composition, their fluorine content or their crosslinking mechanism.

Types

On the basis of their chemical composition FKMs can be divided into the following types

Type 1

FKMs are composed of vinylidene fluoride (VDF) and hexafluoropropylene (HFP). Copolymers are the standard type of FKMs showing a good overall performance. Their fluorine content typically ranges around 66 weight percent.

Type 2

FKMs are composed of VDF, HFP, and tetrafluoroethylene (TFE). Terpolymers have a higher fluorine content compared to copolymers (typically between 68 and 69 weight percent fluorine), which results in better chemical and heat resistance. Compression set and low temperature flexibility may be affected negatively.

Type 3

FKMs are composed of VDF, TFE, and perfluoromethylvinylether (PMVE). The addition of PMVE provides better low temperature flexibility compared to copolymers and terpolymers. Typically the fluorine content of type 3 FKMs ranges from 62 to 68 weight percent.

Type 4

FKMs are composed of propylene, TFE, and VDF. While base resistance is increased in type 4 FKMs, their swelling properties especially in hydrocarbons are worsened. Typically they have a fluorine content of about 67 weight percent.

Type 5

FKMs are composed of VDF, HFP, TFE, PMVE, and Ethylene. Type 5 FKM is known for base resistance and high temperature hydrogen sulfide resistance.

FKM advantages

Excellent temperature resistance

High chemical stability

Good weather, aging and oxygen stability

Excellent resistance in mineral oils and fats

Low gas permeability

Very good resistance in non-polar media

Temperature range from –40 °C to +225 °C

Chemical Resistance and Stability

The chemical resistance and high temperature stability is due to the bulkiness of the fluorine atoms, shielding the polymer backbone and carbon-fluor bond from attack, and the high bonding energy of the carbon-fluor bond, as illustrated in the following figures.

Fkm temperature range

The typical service temperature of FKMs is between -20°C (-5°F) and +230°C (+445°F). They can, however, withstand temperatures up to 300°C for a short period of time.

Hardness (Shore A): 55 to 90.

FKM Applications

On the basis of their chemical composition FKMs can be divided into the following types

Aerospace

O-ring seals in fuels, lubricants, Valve stem seals, Fuel hoses, Fuel Injector O-rings, In tank and quick connect, Flue duct exp. Joints, Valve liners, Roll covers, Sheet stock/cut gaskets etc.

Automotive

Shaft seals, Check valve balls, Diaphragms, Military flare binders, Electrical connectors, Tire valve stem seals, Clips for jet engines, Lathe cut gaskets etc.

Industrial

Hydraulic o-ring seals and hydraulic systems, Manifold gaskets, Fuel tank bladders, Firewall seals, Engine lube siphon hose fuel system seals, Gaskets (valve & manifold) etc.

Fkm products manufactured by us

Polyurethane

We at horiaki india pvt ltd , have vast expertise and experience in manufacturing thermoplastic polyurethanes i.e., TPU as elastomers for products like polyurethane dampers and bearings and bushes.

WHAT are polyurethanes?

Polyurethanes are formed by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives. Because a variety of diisocyanates and a wide range of polyols can be used to produce polyurethane, a broad spectrum of materials can be produced to meet the needs of specific applications.

Types of Polyurethane

Flexible Polyurethane Foam

Flexible polyurethane foam is used as cushioning for a variety of consumer and commercial products, including bedding, furniture, automotive interiors, carpet underlay and packaging. Flexible foam can be created in almost any variety of shapes and firmness. It is light, durable, supportive and comfortable.

Flexible polyurethane foam accounts for about 30 percent of the entire North American polyurethane market, and is used largely for bedding, furniture and in the automotive industry.

Rigid Polyurethane Foam

Rigid polyurethane and polyisocyanurate (polyiso) foams create one of the world’s most popular, energy-efficient and versatile insulations. These foams can significantly cut energy costs while making commercial and residential properties more efficient and comfortable.

According to the U.S. Department of Energy, heating and cooling account for about 56 percent of the energy use in a typical U.S. home, making it the largest energy expense for most homes. To maintain uniform temperature and lower noise levels in homes and commercial properties, builders turn to rigid polyurethane and polyisocyanurate foam. These foams are effective insulation materials that can be used in roof and wall insulation, insulated windows, doors and air barrier sealants.

Coatings, Adhesives, Sealants and Elastomers (CASE)

The uses of polyurethanes in the coatings, adhesives, sealants and elastomers (CASE) market offer a broad and growing spectrum of applications and benefits. Polyurethane coatings can enhance a product’s appearance and lengthen its lifespan. Polyurethane adhesives can provide strong bonding advantages, while polyurethane sealants provide tighter seals. Polyurethane elastomers can be molded into almost any shape, are lighter than metal, offer superior stress recovery and can be resistant to many environmental factors.

Thermoplastic polyurethane (TPU)

Thermoplastic polyurethane (TPU) offers a myriad of physical property combinations and processing applications. It is highly elastic, flexible and resistant to abrasion, impact and weather. TPUs can be colored or fabricated in a wide variety of methods and their use can increase a product’s overall durability.

TPU is an elastomer that is fully thermoplastic. Like all thermoplastic elastomers, TPU is elastic and melt-processable. In addition, it can be processed on extrusion, injection, blow and compression molding equipment. It can be vacuum-formed or solution-coated and is well suited for a wide variety of fabrication methodologies. TPU can provide a considerable number of physical property combinations, making it an extremely flexible material adaptable to dozens of uses such as construction, automotive and footwear.

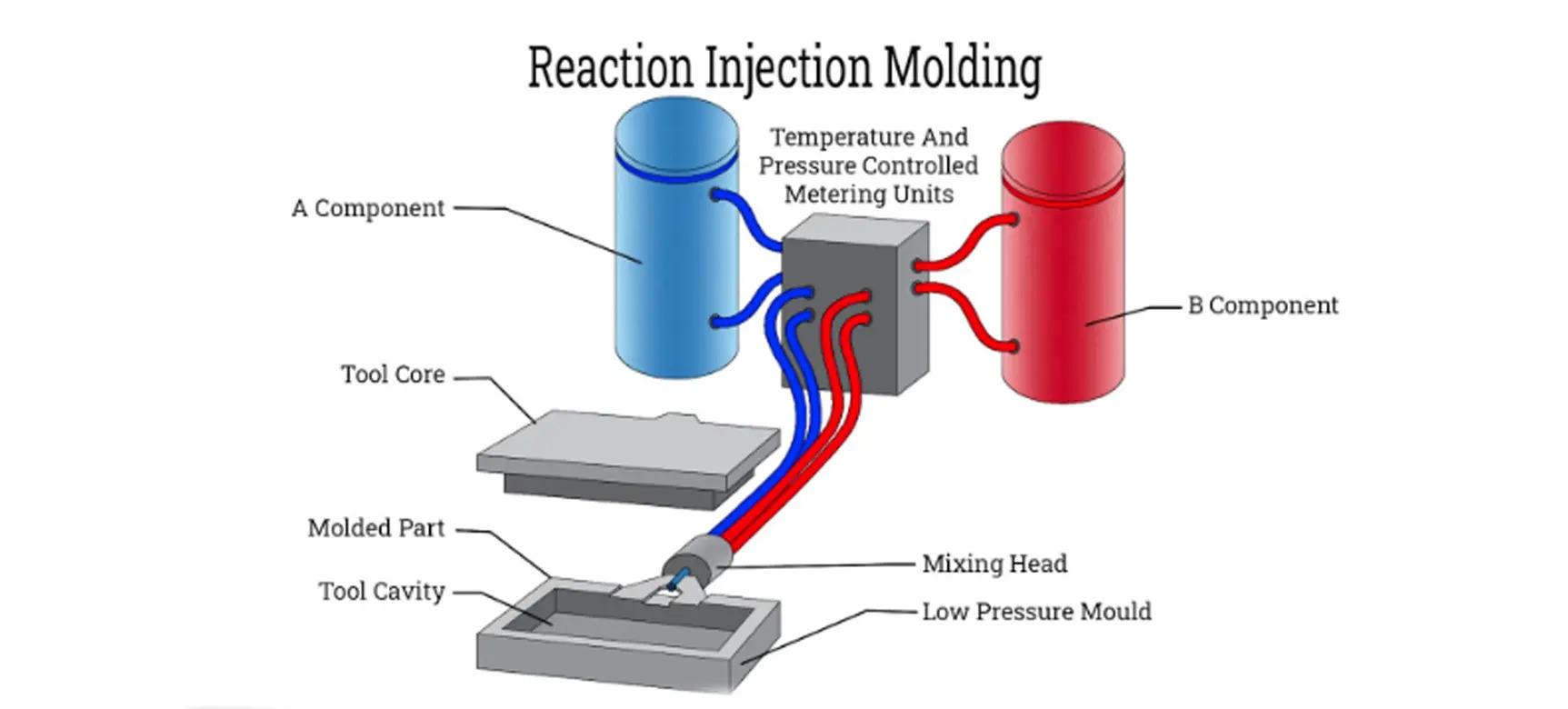

Reaction Injection Molding (RIM)

Car bumpers, electrical housing panels and computer and telecommunication equipment enclosures are some of the parts produced with polyurethanes using reaction injection molding (RIM). Adding design flexibility, the polyurethane RIM process produces parts that are usually not achievable using typical injection molding processes, such as thick- and thin-walled parts, encapsulated inners and foamed cores. In addition to high strength and low weight, polyurethane RIM parts can exhibit heat resistance, thermal insulation, dimensional stability and a high level of dynamic properties. Automotive, construction, appliance, furniture and recreation and sporting goods are a few of the markets and applications using RIM technology.

Binders

Polyurethane binders are used to adhere numerous types of particles and fibers to each other. Their primary areas of use are in the manufacturing of wood panels, rubber or elastomeric flooring surfaces and sand casting for the foundry industry. The highest volume application for polyurethane binders is in the manufacture of Oriented Strand Board (OSB). These wood panels are used in structural sheathing and flooring, manufactured housing, joists and beams and shop panels. Rebond carpet underlay uses polyurethane binders to adhere scrap pieces of foam, which are often flexible polyurethane foam, together in its production.

Waterborne Polyurethane Dispersions (PUDs)

Waterborne polyurethane dispersions (PUDs) are coatings and adhesives that use water as the primary solvent. With increasing federal regulation on the amount of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that can be emitted into the atmosphere, PUDs are being used in more industrial and commercial applications.

USES OF POLYURETHANE DAMPERS

Vibration damping is an important part of building machines or working factories. When you’re talking about situations in which there are lots of moving parts and lots of friction, you definitely need to be able to control vibrations. Excess vibrations can create unnecessary noise, break a machine’s moving parts down more quickly, or even cause the machine to come apart of stop working sooner rather than later.

There are many different ways to control vibration. One is to simply absorb it. This is a process known as vibration damping.

FFKM

FFKM, or perfluoroelastomer, contains higher amounts of fluorine than standard FKM, and features higher temperature ratings, up to approximately 325°C. FFKM also has improved chemical resistance, with nearly universal chemical compatibility. This combination of high-performance capabilities makes FFKM seals the premium choice for the most challenging applications.

The first commercially available FFKM seal was produced in the late 1960s. However, widespread manufacturing of FFKM materials did not occur until the late 1980s due to patent restrictions.

FFKM is used in o-rings and seals in environments with high temperatures and/or harsh chemicals in the aerospace, semiconductor, energy, pharmaceutical and industrial industries.

FFKMs (by ASTM 1418 standard) (equivalent to FFPMs by ISO/DIN 1629 standard) are perfluoroelastomeric compounds containing an even higher amount of fluorine than FKM. They have further improved resistance to high temperatures[1] and chemicals and even withstand environments where Oxygen-Plasma are present for many hours. Certain grades have a maximum continuous service temperature of 327 °C (621 °F). They are commonly used to make O-rings and gaskets that are used in applications that involve contact with hydrocarbons or highly corrosive fluids, or when a wide range of temperatures is encountered.

For vacuum applications, demanding very low contamination (out-gassing and particle emission) as well as high temperature operation (200 – 300 °C) for prolonged out-baking or processing times and where a copper or metal sealing is not possible or very inconvenient/expensive, a custom-made, clean-room manufactured, sealing such as Kalrez® 9100, SCVBR or Perlast can be used. After manufacturing, they are O-plasma vacuum cleaned (and/or vacuum baked) to reach out-gassing performance similar to Teflon while reaching vacuum leak tightness (permeability rates) similar to FKM (Viton) compounds. This combination of properties allows FFKM seals to reach well into UHV pressures without the use of metal sealing. However, they are significantly more expensive than standard FKM O-rings.