Machinery by virtue of its design has reciprocating or rotating parts, creates vibration to some degree through imbalance of the moving parts. With increasing sophistication of industrial setup and machinery, there is rising need to control vibration and noise. To capture this evolving need of our customers, we are proud to offer Anti Vibration Mounts as part of our product range. We offer high quality Anti Vibration Mounts in India and international market that are designed to help reduce transmission of the mechanical vibrations to other non insulated adjacent structures, giving rise to problems of noise and vibration transmission.

Made from premium quality raw materials, the Anti Vibration Mounts that we offer are sure to stand the test of time and protect your expensive and high tech machinery from unnecessary wear and tear. We also offer complete customization facility for this anti Vibration product to ensure that clients find the exact kind of mount that is compatible with their machinery and setup. Praised by customers for its quality and effective operations, this product has placed us among the elite Anti Vibration Mounts Manufacturers.

Products list in catalogue is given below

Stalastic Rubber-Metal Buffers Type C

Stalastic Rubber-Metal Stop Bumpers Type D

Stalastic Rubber-Metal Stop Bumpers Type E

Stalastic Rubber-Metal Stop Bumpers with parabolic croos-section

Stalastic Rubber-Metal Buffers with enlarged bonding surface

Stalastic Bars

Stalastic Rubber-Metal Bars with projecting base plate

Stalastic Rubber-Metal Machine Mountings

Stalastic Rubber-Metal Ceiling Element

Stalastic Rubber-Metal U-Bearing

Stalastic Rubber-Metal Ring Elements

Stalastic Rubber-Metal Annular Buffers

Stalastic Rubber-Metal Ring

Stalastic Rubber Stops No. 1310

Stalastic Rubber-Metal Buffer No. 1311 with base plate

Stalastic Rubber-Metal Buffer No. 1311a with reinforced base plate

Stalastic Rubber-Metal Machine Mountings with stop plate

Stalastic Rubber-Metal Machine Mounting with increased protection against splitting apart

Stalastic Machine Mountings with height adjustment (also available in stainless steel)

Stalastic Rubber-Metal Cones

Stalastic Rubber-Metal Bushes

Stalastic Rubber-Metal HL Bushes - tolerance fields

Stalastic Rubber-Metal AS Bushes

Stalastic Rubber-Metal Suspension Mounts

Stalastic Rubber-Metal Buffer No. 1312 with threaded stud

Stalastic Rubber-Metal Buffers

Stalastic Stop Buffer made of cellular polyurethane with central fixing

Stalastic Rubber-Metal bearing

Stalastic Stop Buffer made of cellular polyurethane with base plate

Stalastic Rubber-Metal Buffers Type A

Stalastic Rubber-Metal Buffers Type B

Stalastic Transformer Bearings

The elite manufacturer of anti vibration mounts, Horiaki offers complete customization facility for all products. It is praised by customers in Germany,UK,Europe for its quality.

What are vibration mounts and why are they needed?

Vibration isolation mounts protect machinery by reducing the amplitude and frequency of vibrational waves. Applications such as large motors and industrial machines generate powerful vibrations and excessive noise when active. Those vibrations cause damage to the equipment and create unsafe working conditions. Eventually this adversely affects product quality and can even bring production to a stop.

Vibration damping mounts are commonly made with an elastomer such as natural rubber which is then bonded to metal. Acting like a shock absorber, our vibration mounts allow motors and machines to operate more quietly and efficiently.

Common mount applications include: Pumps, Hoppers, Roll Mills, Cameras, CNC Machinery, Military Equipment, Washing Machines, Industrial Boat Engines, Small Electric Motors, HVAC Systems, Vibrating Tables, Aviation Equipment, Compressors, Transformers, Shipping Containers, Defense Equipment and Marine Propulsion Engines.

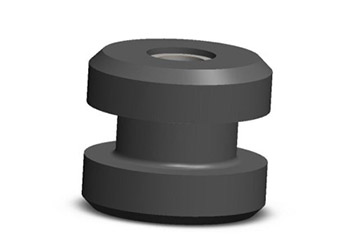

RUBBER BOBBINS

DESCRIPTION:

Rubber Bobbins (Buffers) are a popular and cost-effective solution for protecting a wide range of equipment from shock and vibrations. They have a wide range of uses, from industrial and automotive applications to electrical equipment.

MACHINE FEET

Machine feet and Triflex mounts are available in a variety of sizes and styles, to suit both heavy duty machinery and lighter weight precision applications. Different designs of machine foot can be offered, either with or without rebound control and with a variety of fitment/installation configurations. All machine feet are produced in a range of rubber hardness options.

BUFFER RAILS

DESCRIPTION:

Rectangular buffers can be cut from buffer rails. The buffer rail can be manufactured in lengths and can be cut or drilled to suit the individual customer’s needs. Various different configurations are available . Please contact for more information with regard to our buffer rails .

CONE MOUNTS

DESCRIPTION:

Cone mounts are designed to provide a captive solution and offer progressive stiffness characteristics. They are generally supplied with protective overload and rebound washers to limit movement under high shock loads. Cone mountings can also be referred to as cab mounts. Different rubber compound options can be offered to suit specific environmental conditions.

COMPACTOR MOUNTS

DESCRIPTION:

Plate compactor mounts, roller mounts, waisted mounts and drum mounts, all of which are supplied to major international OEMS for use on walk-behind rollers, ride-on rollers, plate compactors and towed rollers. In this type of application, very high levels of mechanically induced vibration and impact forces need to be isolated. These heavy duty compactor mounts are designed to provide isolation of the vibrating drum or plate whilst preventing wear and fatigue on moving parts.

RUBBER MOUNTS

DESCRIPTION:

A range of rubber mounts suitable for various applications can be manufactured. Their simple design allows for easy installation, and restricts movement in both vertical directions thereby offering a good level of shock protection. Standard rubber mountings are manufactured in chloroprene rubber, which provides good resistance to oils and greases. Other rubber compounds can be offered to suit different environmental conditions.

ELASTOMERIC MOUNTS

DESCRIPTION:

Elastomeric Mounts provide multi-axis protection from shock and vibrations, helping reduce noise. Elastomeric mounts can be produced in a range of rubber compounds and hardness’ to suit the application requirements. Different metals are possible for Elastomeric mounts including steel, stainless steel and aluminium.

LEVELLING FEET

DESCRIPTION:

Levelling feet are designed to keep machines level when placed on uneven or sloped ground. Otherwise known as adjustable equipment feet, they are available to order in a wide variety of size and load capacity combinations. Our levelling foot collection will also help to reduce harmful vibrations. We can design our feet to incorporate noise-absorbing materials for a quieter, work environment. Materials that we can use to create our adjustable levelling feet include plated steel, stainless steel and polyamide.

SANDWICH MOUNTS

DESCRIPTION:

Sandwich mounts are made from rubber sandwiched between two metal plates (they can also be called rectangular mounts). A range of sandwich mount sizes and styles can be manufactured, incorporating mounting holes and/or stud fastenings and one or more metal interleaves.

BENEFITS:

These mounts provide the benefit of the possibility of different stiffness’ in the three directions of loading. They are simple in construction and are used in a wide range of applications including engine mounts, screen conveyor mounts and as general springs for vibratory equipment.

Products list in catalogue is given below

DESCRIPTION:

Marine and industrial engine mounts are used to isolate vibrations and shocks while reducing noise in mobile and stationary equipment. Our engine mounts are made with premium industrial grade materials which stay in service longer than cheaper mounts, prolonging the life of your equipment.

Our most popular marine engine mounts (MM, DS, DH, DM) have an interlocking metal component which acts as a fail-safe protection device; this extends the service life of the mount while protecting your equipment. They are also built with strong, resistant metal which protects the rubber in the mount from damaging fuels, oils, water, petroleum and harsh environmental conditions.

These mounts are commonly used in applications which require drive systems to maintain proper alignment. If an insufficient or worn out mount is installed, the engine will progressively sit lower until it is moved completely out of alignment which makes it work harder to maintain operation. This increases the vibrations and wear of the entire drive of the vessel, eventually wearing out the engine.

Stainless steel (304) is available for corrosive environments to protect against destructive fuels, oils, water and petroleum based products, this extends the service life of the mount and your equipment. Height adjusters are available for all marine engine mounts.

MM Mounts

DESCRIPTION:

MM mounts are used in a wide variety of applications from generator sets to marine engines to provide effective noise and vibration isolation. MM mounts have a compact low profile design, making them very easy to install. The rubber is loaded in shear and compression and 3-way axis control is provided with high vertical elasticity, increased longitudinal stiffness and optimal lateral stiffness for improved vibration isolation.

These mounts can withstand the powerful propeller thrust of marine applications and their rugged design limits excessive movements under shock loads. The protective finish resists corrosion and the top metal cover protects the mount against oil and other liquids.

Size range available is from 77 to 6613 lbs. per MM mount. Applications: Pumps, Compressors, Diesel and Gas Generator Sets, Mobile Electrical Panels and Marine, Industrial and Vehicle Engines.

DS and DH Mounts

DESCRIPTION:

DS and DH engine mounts look similar; however, they are used for different purposes. DS mounts are identified by their high-profile design while DH mounts are identified by their low-profile design. Use DS mounts when maximum vibration isolation is a priority. Use DH mounts when stability is a priority. These mounts perform well in environmental conditions where dripping oil, diesel and harsh elements are present.

DS Mounts

DESCRIPTION:

DS mounts have a high profile rubber section which produces larger deflections and low natural frequencies. These mounts work the rubber in shear and compression. DS mounts are used in applications where maximum vibration isolation is a priority such as in rotating or mobile machines that are continuously subjected to shocks.

Size range available is from 66 to 9259 lbs. per DS mountApplications: Diesel and Gas Generator Sets, Marine Auxiliary Engines, Centrifuges, Mobile Machines, Industrial and Diesel Boat Engines and Motors.

DH Mounts

DESCRIPTION:

DH mounts have a low profile which provides an optimal ratio of stiffness and horizontal stability. These marine engine mounts work the rubber in shear and compression. DH mounts are used in applications that require greater control of movement due to axial and radial shock forces, these mounts will provide a reasonable amount of vibration and noise isolation.

Size range available is from 154 to 11023 lbs. per DH mount.

Applications: Marine-Land Auxiliary Units, Industrial Vehicles, Centrifuges, Ventilators, Compressors and Pumps.

DM Mounts

DESCRIPTION:

DM mounts are similar in design to the DS and DH mounts but are made with a special high-damping rubber compound which provides a high degree of vibration isolation and a great amount of stability. DM mounts are extremely effective on 1, 2 and 3 cylinder diesel engines where the special high-damping compound provides effective vibration isolation capabilities while also eliminating much of the movement created by 1-3 cylinder engines.

Diesel engines with an uneven number of small diameter cylinders create high-amplitude vibrations which require a mount with extra damping capabilities to limit the high amplitudes. These vibration mounts are typically used when other mounts cannot offer sufficient stability to the affected equipment. DM mounts great for machines that are subject to constant start/stop conditions and that require a high degree of vibration damping and in conditions which are close to the frequency of resonance of the system.

Size range available is from 154 to 286 lbs. per DM mount.

Applications: Diesel Engines, Emergency Power Packs, Motor Pumps, Industrial Generator Sets, Compressors and Ventilators.

DF Mounts

DESCRIPTION:

DF mounts also called dual flex engine mounts can be installed on a wide variety of engines including caterpillar and cummins diesel engines, as well as ford, perkins, yanmar and john deere engines.

Cylindrical Mounts

DESCRIPTION:

Cylindrical mounts are made with the finest quality rubber and metal to meet the most demanding requirements for effective vibration isolation and noise damping over a wide range of frequencies while managing motion. Cylindrical mounts, also called cylindrical bobbins or bobbin mounts are commonly used for both active and passive vibration suppression as well as shock and structure-borne noise control. Cylindrical vibration isolators can be installed in both compression and shear designs.

Each cylindrical mount is available with natural rubber as well as specialized compounds as seen below.

Additional compounds available: Chloroprene (Baypren, Neoprene), Ethylene Propylene Terpolymer, Ntrile Butadine (Perbunan), Styrene Butadiene, Butyl, Polyurethane, Silicone Rubber and Fluorocarbon (Viton). Stainless steel threads are available for substantial volume orders.

Types of Cylindrical Mounts

All the following mounts can be loaded in shear or compression. Stainless steel threads are available by request as well as non-standard thread lengths. These mounts can also be made with specialized compounds, see above for details.

Type A - Male/Male

Type A male/male cylindrical mounts have male threads on both sides of the mount. Metric, UNC and UNF threads are available.

Type B - Male/Female

Type B male/female cylindrical mounts have a male thread on one side and a female thread on the other side of the mount. Metric, UNC and UNF threads are available.

Type C - Female/Female

Type C female/female cylindrical mounts have female threads on both sides of the mount. Metric, UNC and UNF threads are available.

Type D - Single Male

Type D single male cylindrical mounts have only one male thread on one side of the mount, the other side is flat. Metric and UNC threads are available.

Type E - Single Female

Type E single female cylindrical mounts have only one female thread on one side of the mount, the other side is flat. Metric and UNC threads are available.

KP-D and KP-E

KP-D and KP-E mounts are often referred to as bumper mounts, rubber bumpers and rubber buffers. These mounts have male threads on both sides.

Benefits Cylindrical Mounts Provide

Simple and effective, cylindrical mounts are easily installed and maintenance free anti vibration mounts.

There are many sizes, studs and threads as well as tapped holes available for a wide variety of applications ranging from protecting sensitive electrical equipment to industrial applications such as shock and vibration reduction, even in commercial grinding machines.

Additional benefits

reduce wear and extend the life of the machinery

increase machine protection

reduced maintenance and repair costs

improved work environment for your employees

reduce shock to floors and foundations

Cylindrical mounts are often used as a buffer or sandwich between two objects such as a motor or fan and a mounting frame. Applications: fans, motors, compressors, grinding machines, hvac equipment, pumps, relays, generator engines, blowers, bumpers, appliances, electric control panels and automotive equipment.

PM Mounts

PM mounts are stationary mounts used to isolate vibration in stationary applications such as generators. There is no fail-safe mechanism on these mounts unlike our MM, DS, DH and DM mounts which can be found on our marine engine mount page.

Applications: engines, CNC machinery, stamping presses, roll mills, motors, pumps, paper machine presses, cable machinery, air compressors, generators and gearboxes.

Sandwich Bar Mounts

Sandwich bar mounts also known as sandwich bars or rail mounts are used to absorb the vibration, movements and shock to protect surrounding equipment. Sandwich bar mounts absorb vibration in shear or compression and can be used as a whole but can also be cut, tapped, drilled and precisely measured to fit any required application. Applications: shipping containers, oil pumps, wind power plates, railroad tracks, standby generators and heavy stationary machinery.

Cone and Shear Mounts

Our anti vibration conical, flex bolt sandwich, square shear, interleaf, v shaped generator, motor and rectangular sandwich mounts are effective vibration isolators while providing noise reduction, high load-bearing capabilities and consistent performance in all applications. Applications range from cab, engine and transmission mounts for trucks and buses to construction and agricultural vehicles.

Stationary Machine Mounts

Our anti vibration stationary machine mounts including vm, pm, kg, sandwich bar, rubber bumper and low frequency ring mounts are made from premium rubber and are effective vibration isolators for a wide variety of applications from large food processing units to small computers.

KG Mounts

KG mounts are heavy duty rubber vibration mounts with exceptional flexible characteristics in both vertical and horizontal planes. They provide deflection up to 30 mm making them suitable for applications with low disturbing frequencies.

Applications: paper and rolling mills, converters, mixers, gearboxes, sound enclosures, industrial fans and floating structures.

Bumper Mounts

Bumper mounts are effective in neutralizing large shock loads and allow soft impact with increasing bending and spring constant which results in the smooth absorption of a large impact force. Bumper mounts also dampen noise and accept a large load deformation with practically no friction. Bumper mounts do not generate noise at the instant of contact, are easy to mount and require no maintenance.

VM Mounts

VM mounts are ideal for isolating low frequency vibrations in all planes (x,y,z) of slow speed machinery and stationary machines as well as shock absorption due to their ability to absorb large deflections at low loads. VM mounts also provide passive vibration isolation on electronic instruments, measuring equipment and test cells. Even though VM mounts provide high deflection, they are compact in weight and are easy to install. Height adjusters are also available for VM mounts. Interchangeable with Novibra® type M mounts.

Applications: HVAC equipment, fans, electronics, vibrating tables, electric motors, pumps, compressors and food processing units.

Shear Mounts

Shear mounts dampen extreme shocks, low frequencies and machine noises. The specially developed rubber in our shear mounts has the outstanding ability to absorb the heat generated by the vibrations which is essential for most applications. The design of our shear mounts is developed for shear and compression. The hourglass shape releases tension, during deflection on bond and rubber, this guarantees the expected performance and is most suitable in shear requirements.

Applications: heavy equipment, compactors, hammers for excavators, springs for vibratory equipment, crushers and generators.

Interleaf Mounts

Interleaf mounts also known as saw or crusher mounts consist of a cylindrical shaped rubber section with naturally bonded interleaf metal plates bonded to two square heavy duty outer metal fixing plates. Interleaf mounts are used to isolate intermittent or continuous vibrations and they allow for static and shock loads in compression as well as also providing high isolation in the horizontal shear direction.

Applications: ultrasonic chambers, transformers, vibrating tables, mills, edge runners, feeder screes, presses, hoppers and grinding machines.

V Shaped Generator Mounts

V shaped generator mounts also known as v shaped generator supports are comprised of two symmetrically-tilted metal parts with a screw on each side. V shaped generator mounts render it possible to make installations which are more elastic than ones usually made with cylindrical or bobbin mounts. In turn, this makes it possible to achieve lower frequencies and improved vibration isolation. Stability is also further enhanced when two are installed, symmetrically opposed. They have two different length screws which facilitate the assembly of the engine to the chassis.

Applications: motor pumps, compressors, hvac units, missile component containers, transmission transfer cases and portable gensets.

Motor Mounts

Motor mounts are used to absorb shocks, vibrations and machine noises in heavy and light equipment. Motor mounts also protect sensitive electric motor or aggregates from incurred movements. They are specially designed to absorb forces in all directions. The rubber used in motor mounts is developed for rough environmental conditions as well as maintain a high load capacity. The premium rubber compound used in our motor mounts is developed for rough environmental conditions so they will last much longer under heavy load.

Applications: agriculture machines, light and heavy construction machines, highway trucks, air compressors, generators and electric motors.

Low Frequency Ring Mounts

Low frequency ring mounts also known as o-mounts are used to control vibration, noise and motion. Low frequency ring mounts will protect sensitive equipment from incurred movements and are specially built to absorb shock, vibration and forces in shear and compression. The rubber hole in the center of the mount reduces the load capacity and increases the deflection which is favorable for low frequency vibration isolation applications as well as high noise reduction requirements.

Applications: air-compressors, printers, electric motors, medical equipment and small sized machinery and instruments.

Conical Mounts

Conical mounts also known as cone mounts isolate shock, motion and vibration in all planes (x,y,z) and if necessary with different loads in each direction to ensure the optimum isolation throughout a wide range of frequencies. Conical mounts have a high load carrying capacity within a compact size that assures a stable solution and are designed with an outer and inner metal sleeve. The shape of both metals are conical for progressive deflection, the outer metal has either a 4 hole or 2 hole flange for easy installation. The supplied washers provide fail safe protection for extreme load in tension or compression that also acts as overload protection to manage excessive g forces. Cone mounts can also be used where the heights of the mounts are critical, as they are designed so that there is minimum protrusion between the securing mount position and the underside of the element to be isolated.

Applications: vehicle bodies, steel frames, commercial or car engines, radiators and cabs.

Flex Bolt Sandwich Mounts

Flex bolt sandwich mounts are used to protect equipment during transportation from shock and to provide vibration isolation. The rubber in our flex bolt sandwich will absorb movements and impact to avoid damage. These mounts can also be found in other transportation vehicles used as noise or vibration isolators on heavy machinery to protect the surrounding equipment. The design of our flex bolt sandwich mounts is developed for shear and compression. The rubber is bonded on two metal plates which can be mounted on each side of the floor, frame or equipment you are using the flex bolt sandwich mounts on.

Applications: missile silos, shipping containers, wind power plates, vibratory feeders and compactor rolling machines, air conditioning/ventilation equipment, motorcycles and other large equipment.

Center Bonded Mounts

Center bonded mounts are used in all types of machinery to dampen vibrations, reduce shocks and limit noise. These mounts are made with the highest quality components with premium rubber designed to provide maximum vibration isolation in all directions, making them perfect for applications such as flexible suspension systems. Their superior construction results in an extended service life with minimal maintenance while providing greater equipment protection when compared to lesser alternatives.

Applications include: engines, pumps, air conditioning units, compressors, cabs, off-road and portable equipment, fuel tanks, mobile and transport mounted equipment, military and agricultural vehicles and industrial machinery

One Piece

One piece mounts have a high load carrying capacity with improved multi-directional resilience and built in rebound protection. They feature an easy to install, permanently bonded, one piece design which balances stability with resilience to withstand high static and shock loads. These mounts feature fail safe protection when installed with available washers.

Two Piece

Two piece mounts are designed for heavy duty applications with dynamic forces in multiple directions such as trucks, commercial vehicles, compressors, generators and HVAC equipment. These mounts are installed through a mounting hole in a support structure and they feature fail safe protection when installed with available washers.

Three Piece

Three piece mounts are used in heavy and light equipment such as agriculture, construction, engines, motors, exhaust and highway vehicles. Therese mounts absorb shocks, vibrations, and noises in all planes. Their design consists of a resilient elastomer that is bonded to a tubular steel inner member, this makes installation simple and improves fatigue life compared to non-bonded designs.

G Series Mounts

G series mounts, used in applications both large and small, are ring shaped and are made with either premium rubber, durable metal or both.

GP Mounts

GP mounts have two rubber sides.

GK Mounts

GK mounts have one metal side and one rubber side.

GH Mounts

GH mounts have two metal sides.

Electrical Panel Mounts

Our anti vibration electrical panel mounts are vibration isolators that provide fail safe protection for wall mounting electrical cabinets for mobile and stationary equipment with disturbing frequencies. These mounts are also known as suspended mounts because they can suspend equipment from vertical walls and ceilings. The upper electrical panel mount can be loaded in shear or tension. The lower electrical panel mount can be loaded in shear or compression. Electrical panel mounts also protect wall-mounted instrument cabinets from vibrations and shocks generated by nearby engines, generators, workshop machinery, etc. They are also suitable to isolate light wall-mounted machines, fans, HVAC equipment, refrigerating units, etc.

Stainless steel metal is available for these mounts.

Harmful vibrations can cause electric devices to fail prematurely because the shocks and vibrations tend to damage the sensitive electrical components. Our electrical panel isolators can prevent this damage because they block the harmful vibrations and shocks from the equipment they are properly installed on.

Applications: electrical panels, electrical enclosures, electric cabinets, electrical boxes and instrument cabinets.

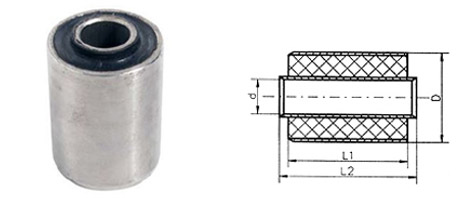

Bushing Mounts

Bushing mounts, also known as bushes or center bonded bushings, are used in applications such as vehicle suspensions which absorb extreme static and dynamic forces while dampening shocks and vibrations. Because of its cylindrical shape, the bushing acts an anti vibration interface between two parts, usually metal objects, without prohibiting movement and increasing flexibility.

Using a fully bonded rubber to metal design, the rubber compound is bonded to both the inner and outer sleeves. This design virtually eliminates high frequencies while supporting high loads in all directions.

We manufacture our bushing mounts in a wide range of metric sizes to suit most applications, we also sell unique bushing sizes and materials.

M Type Fully Bonded Bushing Mounts

Our anti vibration m type fully bonded bushings also known as bushes or center bonded bushings are rubber to metal bonded bushing mounts that are built to absorb extreme static and dynamic forces in applications such as vehicle engines. Our fully bonded bushings have the rubber compound bonded to both inner and outer sleeves. Our bushing vibration isolators are designed to eliminate high frequencies, while supporting high loads in all directions. The bushes are manufactured in a wide range of metric sizes to suit the majority of applications. We also sell our m type bushings in unique sizes or materials to suit your requirements.

Our bushings are pre-loaded using a special process that assures a high resistance to the stresses involved during the operation. Common applications include flexible joints, motor vehicles, earth moving machinery and general machinery and equipment.

| D | d | L1 | L2 |

|---|---|---|---|

| 22 | 10 | 20 | 24 |

| 22 | 12 | 25 | 28 |

| 25 | 10 | 20 | 25 |

| 26 | 8,5 | 25 | 25 |

| 27 | 14 | 40 | 48 |

| 30 | 13 | 40 | 40 |

| 30 | 14 | 25 | 28 |

| 30 | 14 | 67 | 76 |

| 32 | 16 | 50 | 54 |

| 40 | 25 | 20 | 20 |

| 40 | 25 | 30 | 30 |

| 45 | 20 | 60 | 63 |

| 50 | 25 | 30 | 34 |

| 50 | 25 | 65 | 68 |

| 50 | 25 | 80 | 85 |

| 55 | 15,5 | 30 | 16 |

| 60 | 30 | 60 | 68 |

| 62 | 36 | 65 | 71 |

| 64 | 38 | 80 | 88 |

F Type Fully Bonded Bushing Mounts

Our anti vibration f type fully bonded bushings also known as bushes or center bonded bushings are rubber to metal bonded bushing mounts that are built to absorb extreme static and dynamic forces in applications such as vehicle engines. Our fully bonded bushings have the rubber compound bonded to both inner and outer sleeves. Our bushing vibration isolators are designed to eliminate high frequencies, while supporting high loads in all directions. The bushes are manufactured in a wide range of metric sizes to suit the majority of applications. We also sell our f type bushings in unique sizes or materials to suit your requirements.

Our bushings are pre-loaded using a special process that assures a high resistance to the stresses involved during the operation. Common applications include flexible joints, motor vehicles, earth moving machinery and general machinery and equipment.

International Market

- Saudi Arabia, Kuwait, Bahrain , Algeria, Kenya, Tunisia, Angola,Morocco, Senegal, Egypt,Nigeria, Uganda, Libya, Liberia, Swaziland , Switzerland,Vatican City, Iceland, Sweden, Russia, Germany, Poland, Austria, Romania, Spain, Portugal, Hungary, United Kingdom, Denmark,Norway, Netherlands, Italy, Greece etc

Indian Market

Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli Dhanbad, Thiruvanathpuram, Guntur,Guwahati,Patna, Nagpur, Warangal, Dhanbad, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur.