We are proud to present Perfluoroelastomer ffkm o-rings as part of our diverse range of Rubber Moulded products. These are unique type of O Rings that are manufactured using Perfluoroelastomer (FFKM), which is resistant to nearly every chemical class and therefore is ideal to work as a sealant in variety of chemical industrial processes.

FFKM is a family of perfluoroelastomer compounds that contain even higher amounts of fluoride than FKM. FFKM o-rings provide exceptional high temperature and chemical resistance, and can even withstand prolonged exposure to oxygen-plasma. FFKM o-rings can be provided for continuous service in temperatures as high as 621°F (327°C). These o-rings, etc., are commonly used in applications that involve repeated or prolonged contact with hydrocarbons and/or highly corrosive fluids, or those that encounter a wide range of temperatures and retention of sealing force are paramount; these Perfluoroelastomer ffkm o-rings are sure to impress our domestic as well as overseas clients. The unique production materials and impeccable quality of the product has helped it emerge as a favourite in the market. This has also helped us come forward as part of the popular Perfluoroelastomer ffkm o-rings Manufacturers.

FFKM perfluoroelastomer materials are specified by ASTM 1418 standard, and are equivalent to FFPMs by ISO/DIN 1629 standards.

Widely used in chemical processes where purity, high temperatures over 320°C and retention of sealing force are paramount; these Perfluoroelastomer ffkm o-rings are sure to impress our domestic as well as overseas clients. The unique production materials and impeccable quality of the product has helped it emerge as a favourite in the market. This has also helped us come forward as part of the popular Perfluoroelastomer ffkm o-rings Manufacturers .

Features of FFKM seals include

High temperature stability up to 327°C (620°F)

Almost universal chemical resistance

Outstanding mechanical properties

High purity materials

FDA, USP Class VI and 3A compliance

Highest quality parts

Applications: Widely apply to semiconductor, panel, and petrochemical industry. Apply to harsh environment, like etching, film process, high temperature, liquid, strong acid and base.

Why do we prefer FFKM over other material standards?

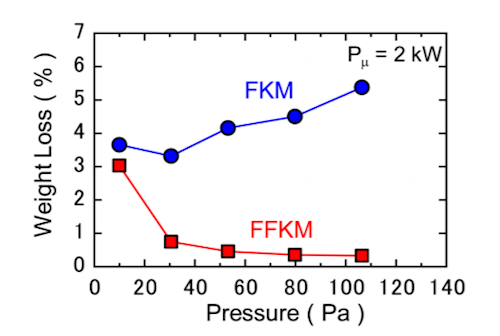

FKM vs. FFKM Comparison?

See a comparison chart for other material compounds here. . Our O Rings offer outstanding performance in demanding operating environments. The chemical and heat resistance of Perfluoroelastomer (FFKM) are similar to those of PTFE. It combines the positive properties of a PTFE O Ring with the elastic behaviour of FKM / Viton O Ring. Perfluoroelastomer / FFKM O Rings are only used if other materials cannot meet the very high application specifications. Typical applications for FFKM O Rings include the Chemical, Aerospace, Oil, High Vacuum Technology and Semi-conductor industries.

Our ffkm o rings standard

1. EQUIVALENT TO KALREZ 6375

| Properties | L | W | HOR76BL | HOR80BL | HOR90BL | HOR60W |

|---|---|---|---|---|---|---|

| Hardness | 75 | 74 | 76 | 80 | 90 | 60 |

| Color | black | white | black | black | black | white |

| 100% Modulus, MPA | 17.5 | 4.5 | 11.6 | 11 | 17 | 4.5 |

| Tensile Strength, MPA | 17.5 | 10 | 15.8 | 18.5 | 21 | 14.1 |

| Elongation % | 177 | 190 | 129 | 150 | 125 | 188 |

| Compression set(%, 70Hr @200°C) | 22 | 25 | 20 | 24 | 30 | 19 |

| Maximum service temperature (continuous) ASTM D412ASTM D2240ASTM D395Bfluorez test method |

230 | 250 | 275 | 250 | 250 | 220 |

2. EQUIVALENT TO KALREZ 4079

| Properties | HRT75BL | HRT75W-1 | HRT90BL | HRT60BL |

|---|---|---|---|---|

| Hardness | 75 | 75 | 90 | 60 |

| Color | black | cream white | black | white |

| 100% Modulus, MPA | 6 | 4.5 | 13.5 | 3.3 |

| Tensile Strength, MPA | 14 | 7.5 | 16.5 | 11 |

| Elongation % | 260 | 262 | 115 | 189 |

| Compression set(%, 70Hr @200°C) | 23 | 24 | 28 | 11 |

| Maximum service temperature (continuous) ASTM D412ASTM D2240ASTM D395Bfluorez test method |

330 | 330 | 330 | 330 |

3. EQUIVALENT TO KALREZ 7075

| Properties | HRS7400 | HRS7401 |

|---|---|---|

| Hardness | 74 | 74 |

| Color | black | black |

| 100% Modulus, MPA | 10.5 | 8.8 |

| Tensile Strength, MPA | 15 | 12.5 |

| Elongation % | 182 | 183 |

| Compression set(%, 70Hr @200°C) | 15 | 12.5 |

| Maximum service temperature (continuous) ASTM D412ASTM D2240ASTM D395Bfluorez test method |

250 | 330 |

4.EQUIVALENT TO KALREZ 8100,9100,9300

| Properties | HRU65T | HRU75T | HRU80W-1 | HRU80W-2 |

|---|---|---|---|---|

| Hardness | 75 | 75 | 90 | 60 |

| Color | black | cream white | black | white |

| 100% Modulus, MPA | 6 | 4.5 | 13.5 | 3.3 |

| Tensile Strength, MPA | 14 | 7.5 | 16.5 | 11 |

| Elongation % | 260 | 262 | 115 | 189 |

| Compression set(%, 70Hr @200°C) | 23 | 24 | 28 | 11 |

| Maximum service temperature (continuous) ASTM D412ASTM D2240ASTM D395Bfluorez test method |

330 | 330 | 330 | 330 |

5. FDA COMPLIANT ( FOOD GRADE )

| Properties | HRF75W | HRF75BL |

|---|---|---|

| Hardness | 75 | 75 |

| Color | White | black |

| 100% Modulus, MPA | 5.8 | 16 |

| Tensile Strength, MPA | 12.2 | 17.5 |

| Elongation % | 215 | 180 |

| Compression set(%, 70Hr @200°C) | 28 | 17 |

| Maximum service temperature (continuous) ASTM D412ASTM D2240ASTM D395Bfluorez test method |

250 | 330 |

Unique production materials and impeccable quality of the product has made Horiaki as the best suppliers and importers in Germany,UK,Europe. It is proud to be Perfluoroelastomer ffkm o-rings manufacturer.

International Market

- Saudi Arabia, Kuwait, Bahrain , Algeria, Kenya, Tunisia, Angola,Morocco, Senegal, Egypt,Nigeria, Uganda, Libya, Liberia, Swaziland , Switzerland,Vatican City, Iceland, Sweden, Russia, Germany, Poland, Austria, Romania, Spain, Portugal, Hungary, United Kingdom, Denmark,Norway, Netherlands, Italy, Greece etc

Indian Market

Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli Dhanbad, Thiruvanathpuram, Guntur,Guwahati,Patna, Nagpur, Warangal, Dhanbad, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur.