Polyurethane Dampers & products are a very important component widely used in different industrial setups and machineries. Keeping the rising need and demand of this product, we at Horiaki have included it in our product catalogue. We offer extraordinary Polyurethane Dampers & products in India as well as to the international market that are widely appreciated for its perfect fit and finish and impeccable quality.

Polyurethane Dampers

Available in loose coil form or manufactured as hose assemblies with a full range of end connections; these Rubber Hoses conform to internationally prescribed quality norms and therefore is sure to meet customer’s expectations. Furthermore, the high tech mechanical setup at Horiaki also allows us to manufacture customized Rubber Hoses in terms of production material and design of the final product. We have very high regard for quality and therefore we test our product for any flaws and errors as far as quality or design flaws are concerned. The superior quality and impeccable finish of this product has helped us cement our place among the top Rubber Hose Manufacturers in India.

Polyurethane Bushings

Customized cast urethane bushings and bearings are used in several automotive parts or industrial equipment because of their advantages over rubber products and their work instruction which allows it to be molded into unique designs to suit varied designs. Polyurethane is stronger and can last for the lifetime of your application as compared to rubber since rubber is biodegradable and is more susceptible to deterioration over time caused by environmental factors.

We at Horiaki India Pvt. Ltd are long term suppliers of several variants of customized Polyurethane bushings and bush stabilizers for major OEMs such as Daimler India Commercial Vehicles and such.

Polyurethane Bushing Characteristics:

High-load bearing capacity

Better compression set

High-tear and cut resistance

Resistant to water, grease, oil, ozone & road debris

Abrasion resistance

Variety of color pigment options.

Applications:

These are just a few examples of the many uses for our polyurethane products like Polyurethane Bushing Suspension Products, Polyurethane Bush Stabilizer, Torque Arm and Control Arm.

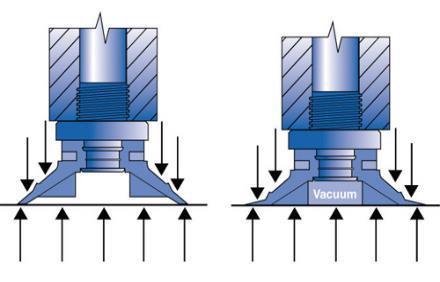

Vacuum Suction cups

- Our product range includes a variety of suction cups with various shapes, sizes and materials, providing the right suction cup for every application. Suction cups consist of an elastomer part and a connection nipple.

- We at Horiaki India (P) Ltd. are the leading Indian source for suction cups, vacuum cups, level compensators, suspensions and vacuum cup mountings, and sealing rings. Unlike competitors, Horiaki is one of the producers. Hence, our customer can always expect consistent quality, great prices, and a large inventory for fast shipping all through out the European, UK and Pan- American markets.

Another variety that we bring to our patrons is Polyurethane Dampers & products! POLURETHANE HANDLE BAR DAMPERS. We offer them in customized specifications as well since they are the vital component in different industrial setups and machineries. Their designing and construction are accomplished as per expert’s guidelines. We are renowned Manufacturer, Exporter and Supplier of Polyurethane Dampers based in Tamil Nadu, India.

The product is designed under observation of experts in line with the client’s feedback and therefore we have been able to offer Polyurethane Dampers & products that meet international quality norms. Backed by our advanced technical setup, we have also developed the ability to offer customization option for Polyurethane Dampers & products to clients, in terms production material composition and design. This has helped us win major multinational corporations who have listed us among the eminent Polyurethane Dampers Manufacturers in india.

- Horiaki is one of the leading Polyurethane dampers & products manufacturing company which offers standard quality products. It is also the best suppliers and importers across Germany,UK,Europe.

Polyurethane

We at horiaki india pvt ltd , have vast expertise and experience in manufacturing thermoplastic polyurethanes i.e., TPU as elastomers for products like polyurethane dampers and bearings and bushes.

WHAT are polyurethanes?

Polyurethanes are formed by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives. Because a variety of diisocyanates and a wide range of polyols can be used to produce polyurethane, a broad spectrum of materials can be produced to meet the needs of specific applications.

Types of Polyurethane

Flexible Polyurethane Foam

Flexible polyurethane foam is used as cushioning for a variety of consumer and commercial products, including bedding, furniture, automotive interiors, carpet underlay and packaging. Flexible foam can be created in almost any variety of shapes and firmness. It is light, durable, supportive and comfortable.

Flexible polyurethane foam accounts for about 30 percent of the entire North American polyurethane market, and is used largely for bedding, furniture and in the automotive industry.

Rigid Polyurethane Foam

Rigid polyurethane and polyisocyanurate (polyiso) foams create one of the world’s most popular, energy-efficient and versatile insulations. These foams can significantly cut energy costs while making commercial and residential properties more efficient and comfortable.

According to the U.S. Department of Energy, heating and cooling account for about 56 percent of the energy use in a typical U.S. home, making it the largest energy expense for most homes. To maintain uniform temperature and lower noise levels in homes and commercial properties, builders turn to rigid polyurethane and polyisocyanurate foam. These foams are effective insulation materials that can be used in roof and wall insulation, insulated windows, doors and air barrier sealants.

Coatings, Adhesives, Sealants and Elastomers (CASE)

The uses of polyurethanes in the coatings, adhesives, sealants and elastomers (CASE) market offer a broad and growing spectrum of applications and benefits. Polyurethane coatings can enhance a product’s appearance and lengthen its lifespan. Polyurethane adhesives can provide strong bonding advantages, while polyurethane sealants provide tighter seals. Polyurethane elastomers can be molded into almost any shape, are lighter than metal, offer superior stress recovery and can be resistant to many environmental factors.

Thermoplastic polyurethane (TPU)

Thermoplastic polyurethane (TPU) offers a myriad of physical property combinations and processing applications. It is highly elastic, flexible and resistant to abrasion, impact and weather. TPUs can be colored or fabricated in a wide variety of methods and their use can increase a product’s overall durability.

TPU is an elastomer that is fully thermoplastic. Like all thermoplastic elastomers, TPU is elastic and melt-processable. In addition, it can be processed on extrusion, injection, blow and compression molding equipment. It can be vacuum-formed or solution-coated and is well suited for a wide variety of fabrication methodologies. TPU can provide a considerable number of physical property combinations, making it an extremely flexible material adaptable to dozens of uses such as construction, automotive and footwear.

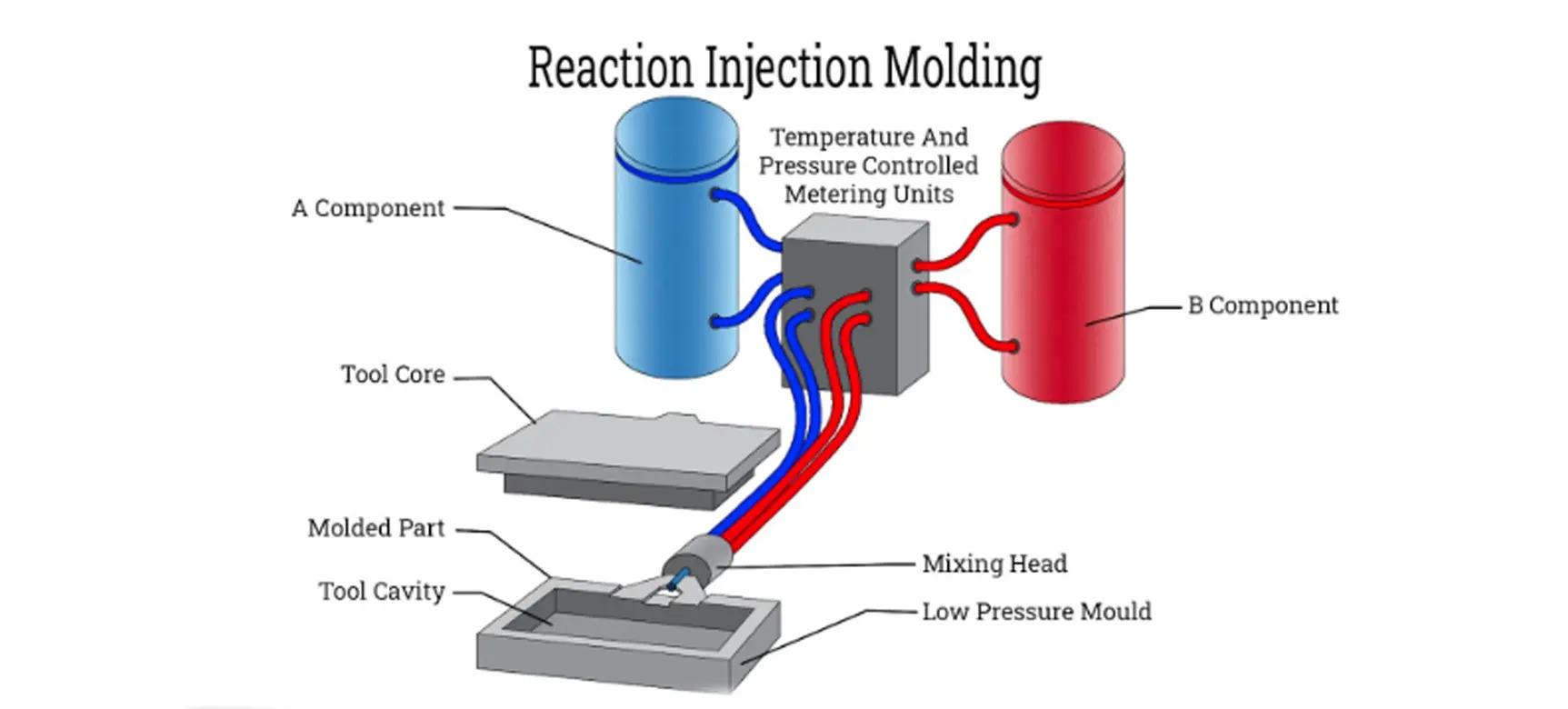

Reaction Injection Molding (RIM)

Car bumpers, electrical housing panels and computer and telecommunication equipment enclosures are some of the parts produced with polyurethanes using reaction injection molding (RIM). Adding design flexibility, the polyurethane RIM process produces parts that are usually not achievable using typical injection molding processes, such as thick- and thin-walled parts, encapsulated inners and foamed cores. In addition to high strength and low weight, polyurethane RIM parts can exhibit heat resistance, thermal insulation, dimensional stability and a high level of dynamic properties. Automotive, construction, appliance, furniture and recreation and sporting goods are a few of the markets and applications using RIM technology.

Binders

Polyurethane binders are used to adhere numerous types of particles and fibers to each other. Their primary areas of use are in the manufacturing of wood panels, rubber or elastomeric flooring surfaces and sand casting for the foundry industry. The highest volume application for polyurethane binders is in the manufacture of Oriented Strand Board (OSB). These wood panels are used in structural sheathing and flooring, manufactured housing, joists and beams and shop panels. Rebond carpet underlay uses polyurethane binders to adhere scrap pieces of foam, which are often flexible polyurethane foam, together in its production.

Waterborne Polyurethane Dispersions (PUDs)

Waterborne polyurethane dispersions (PUDs) are coatings and adhesives that use water as the primary solvent. With increasing federal regulation on the amount of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that can be emitted into the atmosphere, PUDs are being used in more industrial and commercial applications.

USES OF POLYURETHANE DAMPERS

Vibration damping is an important part of building machines or working factories. When you’re talking about situations in which there are lots of moving parts and lots of friction, you definitely need to be able to control vibrations. Excess vibrations can create unnecessary noise, break a machine’s moving parts down more quickly, or even cause the machine to come apart of stop working sooner rather than later.

There are many different ways to control vibration. One is to simply absorb it. This is a process known as vibration damping.

International Market

Saudi Arabia, Kuwait, Bahrain , Algeria, Kenya, Tunisia, Angola,Morocco, Senegal, Egypt,Nigeria, Uganda, Libya, Liberia, Swaziland , Switzerland,Vatican City, Iceland, Sweden, Russia, Germany, Poland, Austria, Romania, Spain, Portugal, Hungary, United Kingdom, Denmark,Norway, Netherlands, Italy, Greece etc

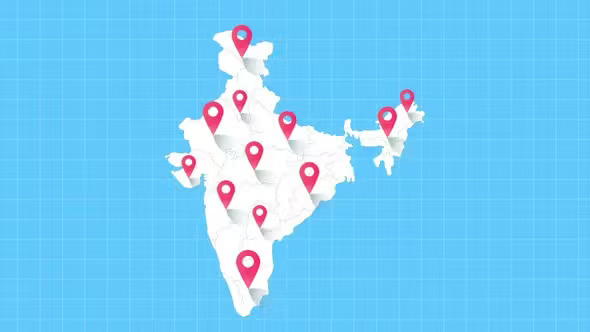

Indian Market

Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli, Dhanbad, Thiruvananthpuram, Guntur, Guwahati, Patna, Nagpur, Warangal, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur