Available in loose coil form or manufactured as hose assemblies with a full range of end connections; these Rubber Hoses conform to internationally prescribed quality norms and therefore is sure to meet customer’s expectations. Furthermore, the high tech mechanical setup at Horiaki also allows us to manufacture customized Rubber Hoses in terms of production material and design of the final product. We have very high regard for quality and therefore we test our product for any flaws and errors as far as quality or design flaws are concerned. The superior quality and impeccable finish of this product has helped us cement our place among the top Rubber Hose Manufacturers in India.

Materials: NR=Natural Rubber(SMR)

Application Field: Water, Closed Loop Water Arrangements, Soluted Lyes at max 50% conc. and mx 80%

Color: Black

Hardness: DIN 53505, Shore A 60-80 +/-5

Density: DIN 53479, g/cm3 1.384

Temperature: approx. +80°C, short-term up to +90°C

Certificates: Approval of own test facility.

Chemical resistance

Vulcanisates of natural rubber (NR) are resistant against: water, seawater, pond water, closed loop water up to 90°C

Partly against alkalines, 50% NaOH at 50°C

Sufficient resistant against natural lighting, weather and ozone

Vulcanisates of natural rubber (NR) are not resistant against:fuel, mineral oils, acids and gases

Application field : The application of NR-vulcanisates is possible where natural media have to be sealed. Temperatures higher than 90°C have to be avoided.

Function and durability : The performance and life of Horiaki gaskets depend in large measure on proper storage and fitting, factors beyond the manufactor’s control.We can, however, vouch for the excellent quality of our products.With this in mind, please also observe our installation instructions.

Rubber Metal Gaskets KTW

The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring

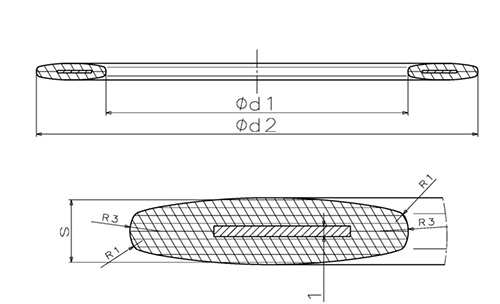

Sizes at the measurement table:

d1 = Inner diameter

d2 = Outer diameter

s = Thickness

Vulcanised rubber gasket, cross section in lens form, rounded edges.

Inside vulcanised steel ring, therefore good reception of the bolt force.

Outer diameter of the gaskets fits to the inner bolt circuit for self centering.

Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40.

DN 15 up to DN 2000

| d2 | |||||||

|---|---|---|---|---|---|---|---|

| DN | s | d1 | PN | ||||

| 6 | 10 | 16 | 25 | 40 | |||

| 15 | 4 | 22 | - | 51 | 51 | 51 | 51 |

| 20 | 4 | 27 | - | 61 | 61 | 61 | 61 |

| 25 | 4 | 34 | - | 71 | 71 | 71 | 71 |

| 32 | 4 | 43 | 76 | 82 | 82 | 82 | 82 |

| 40 | 4 | 49 | - | 92 | 92 | 92 | 92 |

| 50 | 4 | 61 | 96 | 107 | 107 | 107 | 107 |

| 65 | 4 | 77 | 116 | 127 | 127 | 127 | 127 |

| 80 | 4 | 89 | - | 142 | 142 | 142 | 142 |

| 100 | 5 | 115 | 152 | 162 | 162 | 168 | 168 |

| 125 | 5 | 141 | 182 | 192 | 192 | 194 | 194 |

| 150 | 5 | 169 | 207 | 218 | 218 | 224 | 224 |

| 200 | 6 | 220 | 262 | 273 | 273 | 284 | 290 |

| 250 | 6 | 273 | 317 | 328 | 329 | 340 | 352 |

| 300 | 6 | 324 | 373 | 378 | 389 | 400 | 417 |

| 350 | 7 | 356 | 423 | 428 | 444 | 457 | 474 |

| 400 | 7 | 407 | 473 | 489 | 495 | 514 | 546 |

| 450 | 7 | 458 | - | 539 | - | - | - |

| 500 | 7 | 508 | 578 | 594 | 617 | 624 | - |

| 600 | 7 | 610 | 679 | 695 | 734 | 731 | 747 |

| 700 | 8 | 712 | 784 | 810 | 804 | 833 | - |

| 800 | 8 | 813 | 890 | 917 | 911 | 942 | - |

| 900 | 8 | 915 | 990 | 1017 | 1011 | 1042 | - |

| 1000 | 8 | 1016 | 1090 | 1124 | 1128 | 1154 | - |

| 1100 | 8 | 1120 | - | - | 1228 | 1254 | - |

| 1200 | 8 | 1220 | 1307 | 1341 | 1342 | 1364 | - |

| 1400 | 8 | 1420 | 1524 | 1548 | 1542 | 1578 | - |

| 1600 | 8 | 1620 | 1724 | 1772 | 1764 | 1798 | - |

| 1800 | 8 | 1820 | 1931 | 1972 | 1964 | 2000 | - |

| 2000 | 8 | 2020 | 2138 | 2182 | 2168 | 2230 | - |

Rubber Metal Gaskets W270

The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring.

Sizes at the measurement table:

d1 = Inner diameter

d2 = Outer diameter

s = Thickness

Vulcanised rubber gasket, cross section in lens form, rounded edges.

Inside vulcanised steel ring, therefore good reception of the bolt force.

Outer diameter of the gaskets fits to the inner bolt circuit for self centering.

Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40.

DN 15 TO 2000

| d2 | |||||||

|---|---|---|---|---|---|---|---|

| DN | s | d1 | PN | ||||

| 6 | 10 | 16 | 25 | 40 | |||

| 15 | 4 | 22 | - | 51 | 51 | 51 | 51 |

| 20 | 4 | 27 | - | 61 | 61 | 61 | 61 |

| 25 | 4 | 34 | - | 71 | 71 | 71 | 71 |

| 32 | 4 | 43 | 76 | 82 | 82 | 82 | 82 |

| 40 | 4 | 49 | - | 92 | 92 | 92 | 92 |

| 50 | 4 | 61 | 96 | 107 | 107 | 107 | 107 |

| 65 | 4 | 77 | 116 | 127 | 127 | 127 | 127 |

| 80 | 4 | 89 | - | 142 | 142 | 142 | 142 |

| 100 | 5 | 115 | 152 | 162 | 162 | 168 | 168 |

| 125 | 5 | 141 | 182 | 192 | 192 | 194 | 194 |

| 150 | 5 | 169 | 207 | 218 | 218 | 224 | 224 |

| 200 | 6 | 220 | 262 | 273 | 273 | 284 | 290 |

| 250 | 6 | 273 | 317 | 328 | 329 | 340 | 352 |

| 300 | 6 | 324 | 373 | 378 | 389 | 400 | 417 |

| 350 | 7 | 356 | 423 | 428 | 444 | 457 | 474 |

| 400 | 7 | 407 | 473 | 489 | 495 | 514 | 546 |

| 450 | 7 | 458 | - | 539 | - | - | - |

| 500 | 7 | 508 | 578 | 594 | 617 | 624 | - |

| 600 | 7 | 610 | 679 | 695 | 734 | 731 | 747 |

| 700 | 8 | 712 | 784 | 810 | 804 | 833 | - |

| 800 | 8 | 813 | 890 | 917 | 911 | 942 | - |

| 900 | 8 | 915 | 990 | 1017 | 1011 | 1042 | - |

| 1000 | 8 | 1016 | 1090 | 1124 | 1128 | 1154 | - |

| 1100 | 8 | 1120 | - | - | 1228 | 1254 | - |

| 1200 | 8 | 1220 | 1307 | 1341 | 1342 | 1364 | - |

| 1400 | 8 | 1420 | 1524 | 1548 | 1542 | 1578 | - |

| 1600 | 8 | 1620 | 1724 | 1772 | 1764 | 1798 | - |

| 1800 | 8 | 1820 | 1931 | 1972 | 1964 | 2000 | - |

| 2000 | 8 | 2020 | 2138 | 2182 | 2168 | 2230 | - |

Rubber Metal Gaskets- DGVW

The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring.

Sizes at the measurement table:

d1 = Inner diameter

d2 = Outer diameter

s = Thickness

Vulcanised rubber gasket, cross section in lens form, rounded edges.

Inside vulcanised steel ring, therefore good reception of the bolt force.

Outer diameter of the gaskets fits to the inner bolt circuit for self centering.

Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40.

DN 15 TO 2000

| d2 | |||||||

|---|---|---|---|---|---|---|---|

| DN | s | d1 | PN | ||||

| 6 | 10 | 16 | 25 | 40 | |||

| 15 | 4 | 22 | - | 51 | 51 | 51 | 51 |

| 20 | 4 | 27 | - | 61 | 61 | 61 | 61 |

| 25 | 4 | 34 | - | 71 | 71 | 71 | 71 |

| 32 | 4 | 43 | 76 | 82 | 82 | 82 | 82 |

| 40 | 4 | 49 | - | 92 | 92 | 92 | 92 |

| 50 | 4 | 61 | 96 | 107 | 107 | 107 | 107 |

| 65 | 4 | 77 | 116 | 127 | 127 | 127 | 127 |

| 80 | 4 | 89 | - | 142 | 142 | 142 | 142 |

| 100 | 5 | 115 | 152 | 162 | 162 | 168 | 168 |

| 125 | 5 | 141 | 182 | 192 | 192 | 194 | 194 |

| 150 | 5 | 169 | 207 | 218 | 218 | 224 | 224 |

| 200 | 6 | 220 | 262 | 273 | 273 | 284 | 290 |

| 250 | 6 | 273 | 317 | 328 | 329 | 340 | 352 |

| 300 | 6 | 324 | 373 | 378 | 389 | 400 | 417 |

| 350 | 7 | 356 | 423 | 428 | 444 | 457 | 474 |

| 400 | 7 | 407 | 473 | 489 | 495 | 514 | 546 |

| 450 | 7 | 458 | - | 539 | - | - | - |

| 500 | 7 | 508 | 578 | 594 | 617 | 624 | - |

| 600 | 7 | 610 | 679 | 695 | 734 | 731 | 747 |

| 700 | 8 | 712 | 784 | 810 | 804 | 833 | - |

| 800 | 8 | 813 | 890 | 917 | 911 | 942 | - |

| 900 | 8 | 915 | 990 | 1017 | 1011 | 1042 | - |

| 1000 | 8 | 1016 | 1090 | 1124 | 1128 | 1154 | - |

| 1100 | 8 | 1120 | - | - | 1228 | 1254 | - |

| 1200 | 8 | 1220 | 1307 | 1341 | 1342 | 1364 | - |

| 1400 | 8 | 1420 | 1524 | 1548 | 1542 | 1578 | - |

| 1600 | 8 | 1620 | 1724 | 1772 | 1764 | 1798 | - |

| 1800 | 8 | 1820 | 1931 | 1972 | 1964 | 2000 | - |

| 2000 | 8 | 2020 | 2138 | 2182 | 2168 | 2230 | - |

Rubber Metal Gaskets water lines

The gaskets are made of elastomere butadien-rubber in different types -with inside vulcanised steel ring.

Sizes at the measurement table:

d1 = Inner diameter

d2 = Outer diameter

s = Thickness

Vulcanised rubber gasket, cross section in lens form, rounded edges.

Inside vulcanised steel ring, therefore good reception of the bolt force.

Outer diameter of the gaskets fits to the inner bolt circuit for self centering.

Dimension in DIN EN 1514-1 (replaces DIN 2690 ) for the pressure ratings PN 6 to PN 40.

DN 15 TO 2000

| d2 | |||||||

|---|---|---|---|---|---|---|---|

| DN | s | d1 | PN | ||||

| 6 | 10 | 16 | 25 | 40 | |||

| 15 | 4 | 22 | - | 51 | 51 | 51 | 51 |

| 20 | 4 | 27 | - | 61 | 61 | 61 | 61 |

| 25 | 4 | 34 | - | 71 | 71 | 71 | 71 |

| 32 | 4 | 43 | 76 | 82 | 82 | 82 | 82 |

| 40 | 4 | 49 | - | 92 | 92 | 92 | 92 |

| 50 | 4 | 61 | 96 | 107 | 107 | 107 | 107 |

| 65 | 4 | 77 | 116 | 127 | 127 | 127 | 127 |

| 80 | 4 | 89 | - | 142 | 142 | 142 | 142 |

| 100 | 5 | 115 | 152 | 162 | 162 | 168 | 168 |

| 125 | 5 | 141 | 182 | 192 | 192 | 194 | 194 |

| 150 | 5 | 169 | 207 | 218 | 218 | 224 | 224 |

| 200 | 6 | 220 | 262 | 273 | 273 | 284 | 290 |

| 250 | 6 | 273 | 317 | 328 | 329 | 340 | 352 |

| 300 | 6 | 324 | 373 | 378 | 389 | 400 | 417 |

| 350 | 7 | 356 | 423 | 428 | 444 | 457 | 474 |

| 400 | 7 | 407 | 473 | 489 | 495 | 514 | 546 |

| 450 | 7 | 458 | - | 539 | - | - | - |

| 500 | 7 | 508 | 578 | 594 | 617 | 624 | - |

| 600 | 7 | 610 | 679 | 695 | 734 | 731 | 747 |

| 700 | 8 | 712 | 784 | 810 | 804 | 833 | - |

| 800 | 8 | 813 | 890 | 917 | 911 | 942 | - |

| 900 | 8 | 915 | 990 | 1017 | 1011 | 1042 | - |

| 1000 | 8 | 1016 | 1090 | 1124 | 1128 | 1154 | - |

| 1100 | 8 | 1120 | - | - | 1228 | 1254 | - |

| 1200 | 8 | 1220 | 1307 | 1341 | 1342 | 1364 | - |

| 1400 | 8 | 1420 | 1524 | 1548 | 1542 | 1578 | - |

| 1600 | 8 | 1620 | 1724 | 1772 | 1764 | 1798 | - |

| 1800 | 8 | 1820 | 1931 | 1972 | 1964 | 2000 | - |

| 2000 | 8 | 2020 | 2138 | 2182 | 2168 | 2230 | - |

Rubber-Metal-Gaskets – Safe sealing of gases and liquids

Safe sealing of water, gas, air, acids, alkalis and hydrocarbons with low sealing forces at temperatures up to 200°C, depending on the elastomer type.

Rubber-metal-gaskets are used where safe sealing of conventional up to special industrial media such as gases and liquids are required under usual installation conditions like temperatures, pressures and forces

Suitable for all flange materials

A flange connection has to be always treated as a coherent system, because the sealing functions is determined by the interaction of individual elements including flanges, gaskets and screws

| d2 | |||||||

|---|---|---|---|---|---|---|---|

| DN | s | d1 | PN | ||||

| 6 | 10 | 16 | 25 | 40 | |||

| 15 | 4 | 22 | - | 51 | 51 | 51 | 51 |

| 20 | 4 | 27 | - | 61 | 61 | 61 | 61 |

| 25 | 4 | 34 | - | 71 | 71 | 71 | 71 |

| 32 | 4 | 43 | - | 82 | 82 | 82 | 82 |

| 40 | 4 | 49 | - | 92 | 92 | 92 | 92 |

| 50 | 4 | 61 | - | 107 | 107 | 107 | 107 |

| 65 | 4 | 77 | - | 127 | 127 | 127 | 127 |

| 80 | 4 | 89 | - | 142 | 142 | 142 | 142 |

| 100 | 5 | 115 | - | 162 | 162 | 168 | 168 |

| 125 | 5 | 141 | - | 192 | 192 | 194 | 194 |

| 150 | 5 | 169 | - | 218 | 218 | 224 | 224 |

| 200 | 6 | 220 | - | 273 | 273 | 284 | 290 |

| 250 | 6 | 273 | - | 328 | 329 | 340 | - |

| 300 | 6 | 324 | - | 378 | 389 | 400 | - |

| 350 | 7 | 356 | - | 438 | 444 | 457 | - |

| 400 | 7 | 407 | - | 489 | 495 | 514 | - |

| 450 | 7 | 458 | - | 539 | - | - | - |

| 500 | 7 | 508 | - | 594 | 617 | 624 | - |

| 600 | 7 | 610 | - | 695 | 734 | 731 | 747 |

| 700 | 8 | 712 | - | 810 | 804 | - | - |

| 800 | 8 | 813 | - | 917 | 911 | - | - |

| 900 | 8 | 915 | - | 1017 | 1011 | - | - |

| 1000 | 8 | 1016 | - | 1124 | 1128 | - | - |

| 1100 | 8 | 1120 | - | - | - | - | - |

| 1200 | 8 | 1220 | - | 1341 | 1342 | - | - |

| 1400 | 8 | 1420 | - | 1548 | - | - | - |

| 1600 | 8 | 1620 | - | 1772 | - | - | - |

| 1800 | 8 | 1820 | - | 1972 | - | - | - |

| 2000 | 8 | 2020 | - | 2182 | - | - | - |

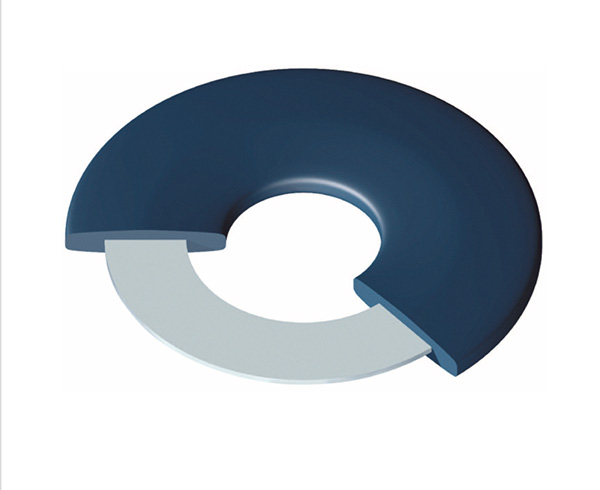

Horiaki HRS

Rubber gasket, lenticular shape, rounded edges. Steel ring, chemically treated, no possibility to separate the elastomers from the steel core. Suitable for flanges made of metal.

Self-centering with the same flange DN and PN appropriate tightening torques

Self-limiting compression surface

Rigid gasket, easy to install

Soft surface in order to seal slightly damaged flange surfaces

Blow-off proof n Materials :NR, NBR, EPDM, CSM, FKM

Dimensions according to EN 1514-1 depending on DN: PN 6 to PN 40 DN 15 up to DN 2000

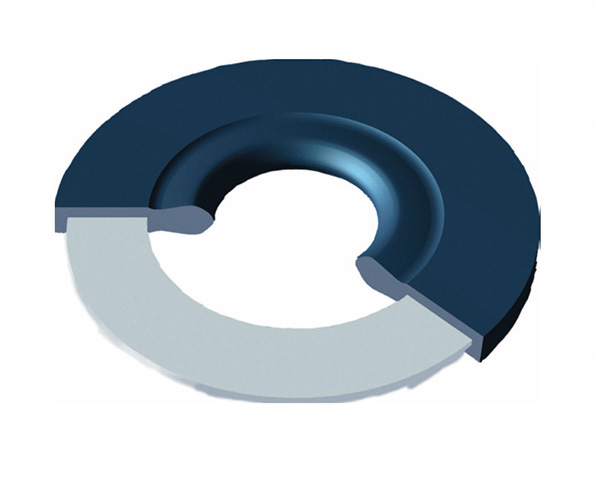

Horiaki HRS/S

Rubber gasket, Lenticular shape at the sealing body, with integrally molded spear tip at the inside diameter of the gasket, rounded edges. The spear tip provides higher safety at lowest contact pressures.. Suitable for installation between flanges made of metal and plastic

Self-centering with the same flange DN and PN

Minimum tightening torques and smaller than HRS (see diagram below)

Materials of HORIAKI HRS/S : NBR, EPDM, FKM, EPDM fire resistant

Dimensions according to EN 1514-1 depending on DN: PN 10 to PN 40 DN 15 up to DN 1000

Horiaki HRS/TS

Rubber gasket, flat shape at the sealing body, with integrally molded spear tip at the inside diameter of the gasket, rectangular outside diameter. The spear tip provides higher safety at lowest contact pressures.

suitable for flanges made of plastics such as PE, PP, GRP, PVC

Self-centering with the same flange DN and SDR

Reduced dead space

Tight, also at low tightening torques

Materials of HORIAKI HRS/TS: NBR, EPDM, FKM

Dimensions according to the valid European standards for plastic tubes made of PE, PP, PVC, PVDF and GRP (mainly SDR 11,17 and 33)

Materials of rubber-metal-gaskets

NR

• Field of application: Water ,Circuit water ,Diluted alkalis up to max. 50% and max. 80°C

• Temperature: approx. +80°C, short-term up to +90°C

• Colour: Black

• Certificates: EN 681 -1 WC Class 70

• Applications: NR vulcanized materials can be used where noncritical media have to be sealed. Higher temperatures than 90°C have to be avoided

NBR

• Field of application: Drinking water, Waste water Process water

• Color: black

• Temperature: from -40°C to +110°C, short-term up to +130°C

• Certification:EN 681 -1 WAL/WCL Class 70 ,Elastomer Guideline (new KTW,) DVGW W270 ACS, WRAS (BS6920), FDA Certificate, TA-Luft (German Clean Air Act)

• Applications of EPDM vulcanized materials mainly result from the good resistance to chemicals. Furthermore, the EPDM quality has a good resistance against ozone and aging.

Epdm

• Field of application: Drinking water, Waste water Process water

• Color: black

• Temperature: from -40°C to +110°C, short-term up to +130°C

• Certification:EN 681 -1 WAL/WCL Class 70 ,Elastomer Guideline (new KTW,) DVGW W270 ACS, WRAS (BS6920), FDA Certificate, TA-Luft (German Clean Air Act)

• Applications of EPDM vulcanized materials mainly result from the good resistance to chemicals. Furthermore, the EPDM quality has a good resistance against ozone and aging.

NBR

• Application in case of higher temperatures (Viton is the brand name of DuPont ® for FKM) in the chemical industry

• COLOR: brown

• Temperature: from -20°C to +200°C

• Certification: TA-Luft (German Clean Air Act)

• Due to the good resistance against acids and alkalis, the main use is in the area of chemistry and their users.

HORIAKI HRS-ptfelon

• Rubber-Metal-Gasket with PTFE jacket

• Gasket material: EPDM ethylene-propylene-rubber developed in accordance with the main European drinking water requirements. Very good properties of resistance against ozon and ageing.

• Material for jacket: Virginal PTFE up to DN 900, modified PTFE from DN 1000

• Dimensions:

• HRS: DN 15 up to DN 2000 acc. to EN 1514-1.

• HRS/TS: DN 16 up to DN 400 SDR 11 and 17

• Application field: Safe sealing of pipe systems where aggresive fluids are flowing. Specially suitable for coated flanges and plastic flanges in PE, PP, PVC and GRP. PTFE is quite against all fluid resistant

International Market

- EUROPE: GERMANY, FRANCE, ITALY, UNITED KINGDOM (UK), DENMARK, NETHERLANDS, SWEDEN, SWITZERLAND, NORWAY, CZECH REPUBLIC, LUXEMBORG, IRELAND, AUSTRIA, BELGIUM, POLAND, SPAIN, CROATIA, GREECE, POLAND, ICELAND, HUNGARY, ROMANIA

- UNITED STATES(USA), CANADA, MEXICO

- RUSSIA

- AUSTRALIA AND NEW ZEALAND

- ASIA: JAPAN, SINGAPORE, MALAYSIA, THAILAND, INDONESIA, CHINA

- Middle East: Saudi Arabia, Kuwait, Qatar, Bahrain. Africa: Algeria, Kenya, Tunisia, Angola, Morocco, Senegal, Egypt, Nigeria, Uganda, Libya, Liberia, Swaziland etc.

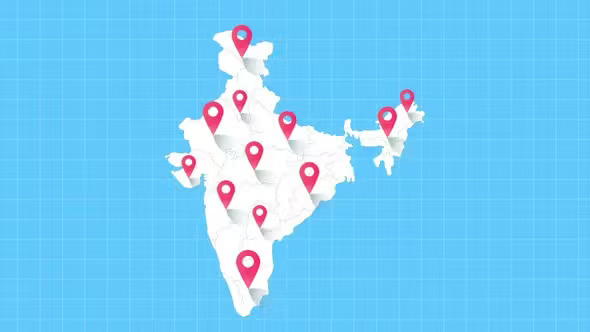

Indian Market

Jammu, Kota, Jalandhar, Jabalpur, Mumbai, Hyderabad, Bareilly, Varanasi, Kolhapur, Pune, Vadodara, Kanpur, Tiruchirappalli, Salem, Nashik, Jaipur, Kolkata, Surat, Delhi, Gorakhpur, Kozhikode, Aligarh, Amravati, Ghaziabad, Bhiwandi, Jamshedpur, Bengaluru, Aurangabad, Ahmedabad, Indore, Hubli, Dhanbad, Thiruvananthpuram, Guntur, Guwahati, Patna, Nagpur, Warangal, Faridabad, Belgaum, Dehradun, Madurai, Amritsar, Chennai, Chandigarh,Durg Bhilai, Meerut, Ludhina, Bhubaneswar, Asansol, Solapur, Agra, Rajkot, Coimbatore, Pondicherry, Bikaner, Bhopal, Moradabad, Vijayawada, Mysore, Allahabad, Cuttack, Jamnagar, Vishapatnam, Ranchi, Srinagar, Tiruppur, Lucknow, Mangalore, Jodhpur, Kochi, Gwalior, Raipur